I’m an IT guy by profession. I’ve taken on standard jobs like network configuration, server builds, website builds, securing servers and websites, software support, written custom software for SuperFlo machines, fixed engine dynos etc.

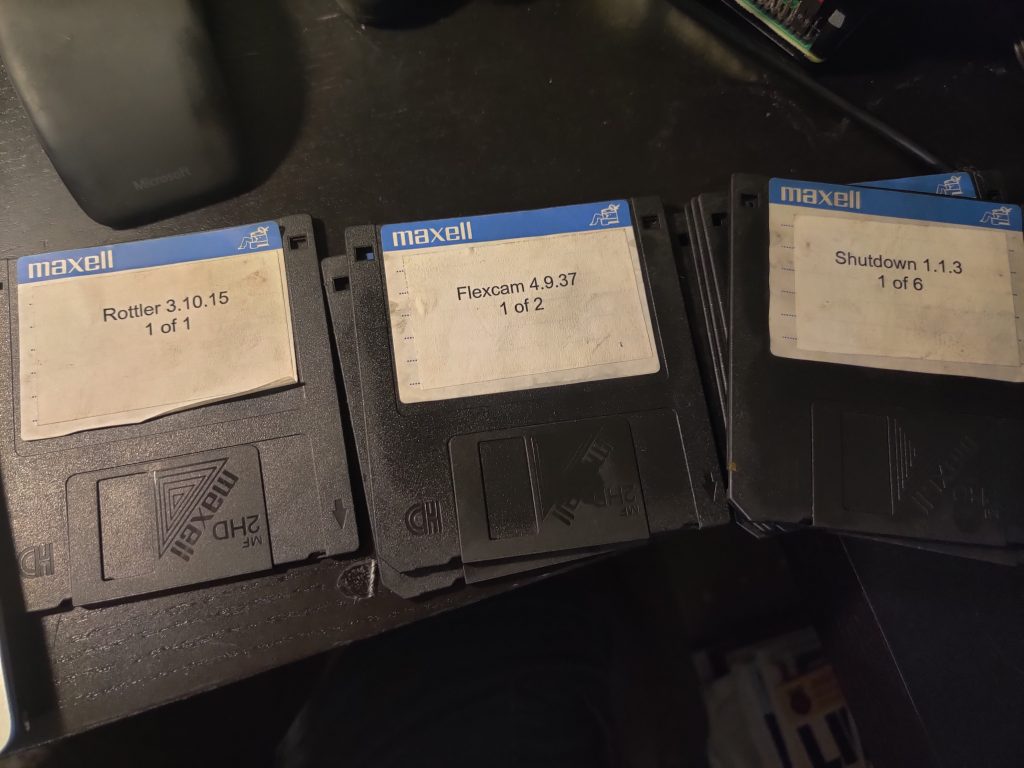

Well a buddy of mine works at a speed shop which does pretty much everything from turbos to high-end engine builds. Their Rottler F-65 CNC had taken a turn for the worst. Not sure how long it had been down, weeks, months, not sure. The problem with the machine wasn’t that it was time to replace it but that it was running an old PC with Windows 98 along with Rottler’s software. They had installation software but they were on floppy disks and in bad shape. The hard drive was bad, couldnt recover any data from it. Rottler MFG did not have a copy of the install software, so pucker factor was high since I had to recover data. I decided to take a crack at it. 🙂

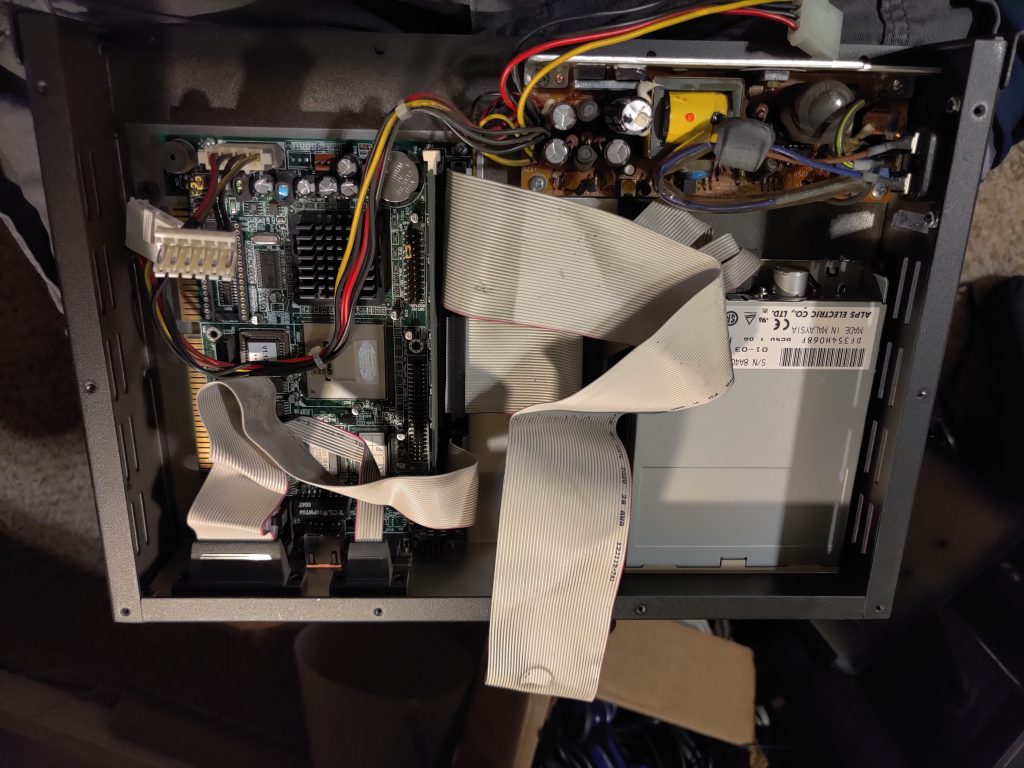

I was able to repair the Actek computer it comes with. Power supply was bad, memory was bad, along with being very dirty. The problem here is that I’d have to Frankenstein it. Power supply no longer available, so it would need to be external. Hard drive is IDE, I could swap it to Compact Flash but then I’d still end up with a machine that runs Windows 98 and if I’m lucky, it’ll keep running for a few years. If it goes bad? Cant find parts.

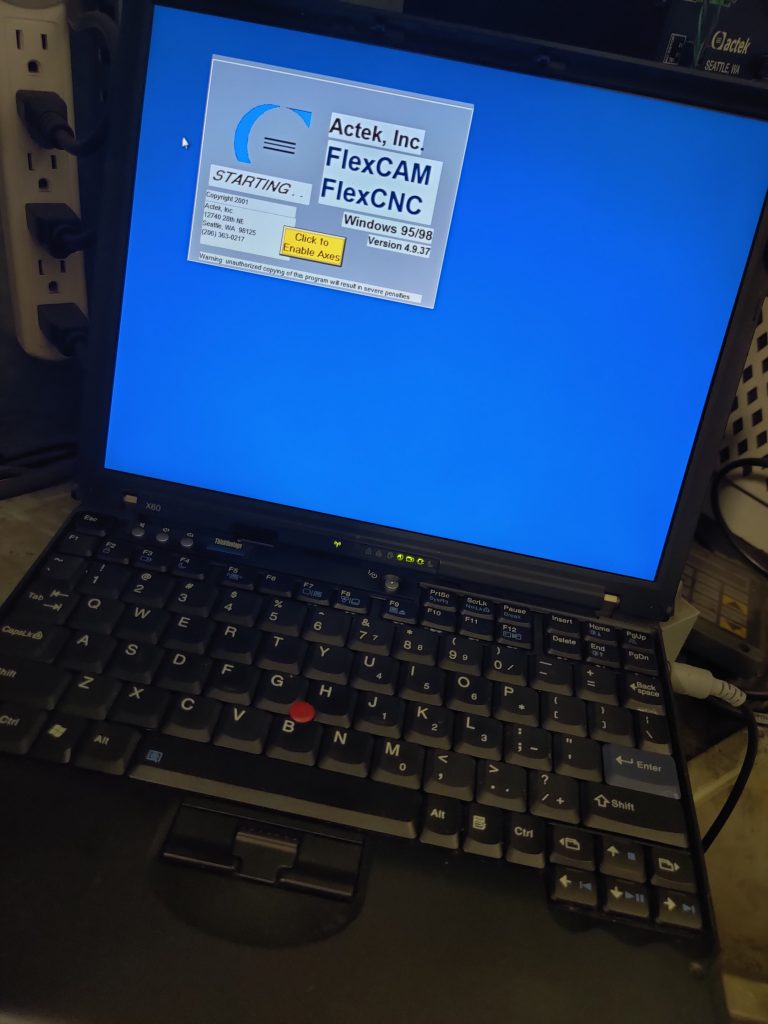

I wrote some software to help me pull data off of the floppy disks. I was able to recover the Rottler and FlexCAM floppys and about 50-60% of Shutdown. Shutdown doesnt look like its needed so I didnt care.

Next test was run it on a VM in VirtualBox in Windows 98. Works fine. Ok, lets test on my spare laptop running Windows 7. Worked! Took it to the client’s shop, hooked up my laptop with a USB to Serial adapter cable and here we go! Pic of it not working below, the internals of the Actek computer and then of it communicating with the F-65 and working on my spare laptop.

I’ll build an industrial mini-pc and transfer Windows 7 along with the Rottler software on it. Then we’ll run a block thru.